ISO13795 Welded Steel Marine Bollard

- Material: Steel Plate & Steel Tube

- Nominal Size: 150mm to 600mm

- SWL: 54kN to 1401kN

- Weight: 29KG to 1391KG

- OEM: Accepted

- Bitt type: Double

- Certificate: CCS, ABS, BV, DNVGL, NKK, etc.

- Surface Treatment: without any visible flaws or imperfections and coated externally with an anti-corrosion protective finish.

ISO13795 Welded Steel Marine Bollard

The welded steel bollard is a double bitt bollard according to the standard of ISO13795, suitable for installation on sea-going vessels to meet normal mooring and towing requirements. The posts of the bollards shall be constructed from steel tubes or formed from the plate. A low-friction surface coating is not recommended so as to increase the holding force of the mooring rope under figure-of-eight belay according to ISO standard. Depending on the construction, the mooring bollards shall be classified as two types, which are Type A – with compact base plate and Type B – with a wide base plate.

For mooring purpose, the maximum load in kN on the rope that should normally be applied in-service conditions. For towing purposes, the maximum load on the rope applied to a bollard subjected to a tug boat pull by using an eye splice at the end of the towing rope to connect to the bollard. And the SWL for mooring and towing are different.

The posts of the bollards shall be constructed from steel tubes or formed from the plates. Both the steel tubes and steel plates should have a yield point of not less than 235N/mm2. The fins of the welded steel bollard shall be installed to keep the ropes as low as possible so as to reduce the loads to the bollard posts from the mooring or towing ropes. And the eye plates for tying the stopping-off rope or chain shall be provided. YSmarines is a professional manufacturer and supplier with superior quality ISO13795 marine bollard, the most affordable price guaranteed.

Features Of ISO13795 Marine Bollard

With smooth edges and surface

Expressed SWL or TOW in tonnes (letter “t”) marking clearly on a surface

International load and stress criteria

The fins and eye plates are provided

Technical Parameters Of ISO13795 Welded Steel Bollard

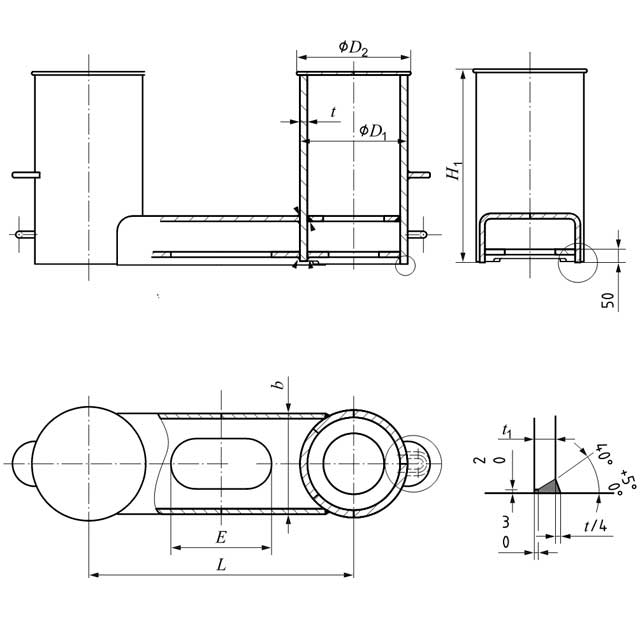

ISO13795 Type A Bollard

Material: weldable steel plates

SWL for one-rope use: 54kN to 1401kN

Base: with a compact base plate

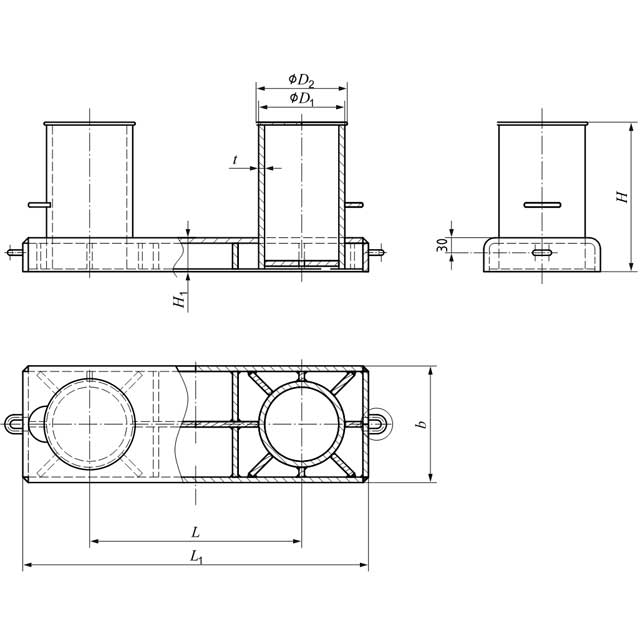

ISO13795 Type B Bollard

Material: weldable steel plates or steel tubes

SWL for one-rope use: 54kN to 1401kN

Base: with a wide base plate

Surface Treatment: without any visible flaws or imperfections and coated externally with an anti-corrosion protective finish.

|

Nominal Size |

Dimensions (mm) | SWL |

Weight | |||||||||||

| For mooring purpose | For towing purpose | |||||||||||||

| D1 | D2 | H1 | B | E | L | t | One-rope use | Two-rope use | ||||||

| (kN) | (t) | (kN) | (t) | (kN) | (t) | (kg) | ||||||||

| 150 | 165.2 | 185 | 330 | 155 | – | 400 | 8 | 54 | 5.5 | 49 | 5 | 383 | 10 | 29 |

| 200 | 216.3 | 240 | 395 | 205 | – | 500 | 8 | 82 | 8.4 | 65 | 6.7 | 579 | 13 | 46 |

| 250A | 267.4 | 290 | 505 | 250 | – | 630 | 12 | 156 | 16 | 134 | 14 | 1315 | 27 | 107 |

| 250B | 267.4 | 290 | 505 | 250 | – | 630 | 10 | 127 | 13 | 108 | 11 | 215 | 22 | 91 |

| 300A | 318.5 | 340 | 600 | 290 | 300 | 800 | 21.5 | 332 | 34 | 306 | 31 | 3365 | 62 | 281 |

| 300B | 318.5 | 340 | 600 | 290 | 300 | 800 | 12 | 186 | 19 | 161 | 16 | 352 | 36 | 166 |

| 350A | 355.6 | 380 | 685 | 340 | 350 | 890 | 26 | 443 | 45 | 418 | 43 | 5062 | 85 | 431 |

| 350B | 355.6 | 380 | 685 | 340 | 350 | 890 | 14 | 244 | 25 | 216 | 22 | 2855 | 50 | 241 |

| 400A | 406.4 | 430 | 730 | 380 | 380 | 1000 | 28 | 594 | 61 | 521 | 53 | 6632 | 106 | 570 |

| 400B | 406.4 | 430 | 730 | 380 | 380 | 1000 | 15 | 326 | 33 | 269 | 27 | 3816 | 67 | 322 |

| 450A | 457.2 | 480 | 770 | 425 | 410 | 1100 | 29 | 753 | 77 | 612 | 62 | 8201 | 124 | 712 |

| 450B | 457.2 | 480 | 770 | 425 | 410 | 1100 | 14.5 | 382 | 39 | 292 | 30 | 4483 | 78 | 379 |

| 500A | 508 | 530 | 830 | 480 | 460 | 1250 | 32 | 992 | 101 | 757 | 77 | 10928 | 154 | 960 |

| 500B | 508 | 530 | 830 | 480 | 460 | 1250 | 14.5 | 457 | 47 | 326 | 33 | 5474 | 93 | 465 |

| 550A | 558.8 | 580 | 900 | 520 | 540 | 1380 | 31 | 1131 | 115 | 812 | 83 | 12635 | 165 | 1123 |

Applications Of ISO13795 Welded Steel Marine Bollard

Sea-going vessels

Inland vessels and boats

Navy vessels

FAQ About ISO13795 Marine Mooring Bollard

1. Can you supply OEM or ODM service?

A: Yes, we have a great research & development team. The marine mooring bollards can be customized according to your request.

2. How to choose between type A and type B?

A: The thickness of posts for type A and type B are different. Type A is thicker than type B, and the SWL of type A is bigger than type B.

3. How to confirm the SWL?

A: The SWL intended for the use of the bollards shall be noted in the towing and mooring plan available onboard for the guidance of the shipmaster as specified in MSC/Circ.1175. The actual SWL on board shall be determined by considering the under deck reinforcement, and it shall be marked on the towing and mooring plan. The actual SWL shall not be over the SWL indicated in ISO13795.