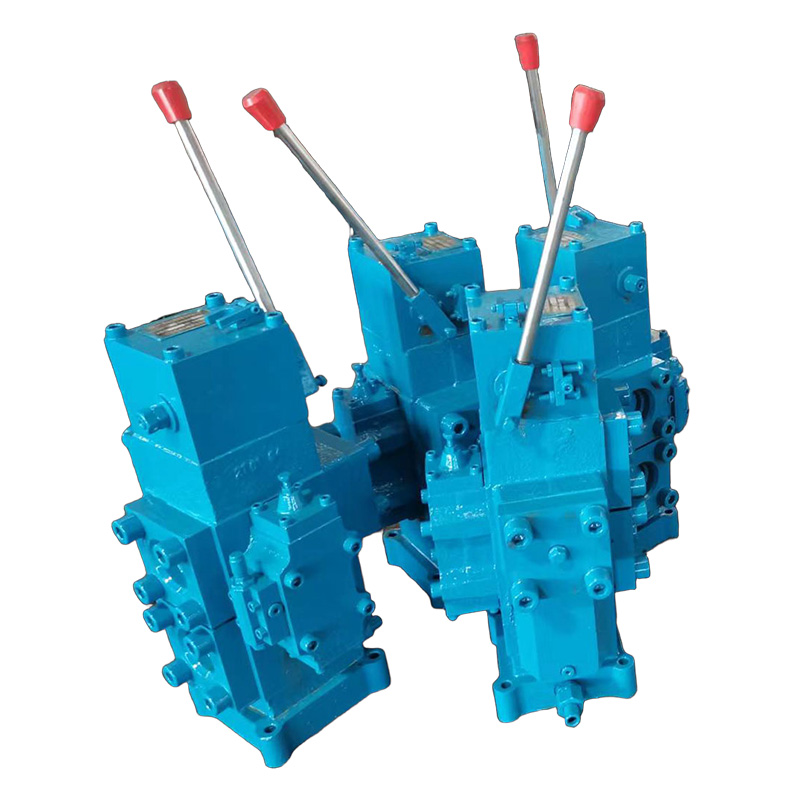

CSBF Manual Proportion/Volume/Direction Compound Valve

- Nominal Dia.: 20-65mm

- Nominal Flow: 120-1200L/min

- Nominal Pressure: 25MPa

- Safety Valve Pressure Range: 5-25MPa

- Handle Operating Force:≤40

Advantages of Using CSBF Manual Proportion/Volume/Direction Compound Valve

- This valve is a three-position, four-way directional control valve with pressure compensation, proportional flow control, and safety protection.

- The operation handle of the valve and the flow-adjusting mechanism perform synchronized actions.

- It supports infinitely variable speed and offers excellent capability for inverting and governing speed.

- It is widely used in shipping machinery and hydraulic systems of other machinery.

- When adapted to a slewing arrangement, it enables remote control operation.

- This product has been granted national patents with patent numbers ZL02318735.2 and ZL02220987.5.

Main Technical Parameters of CSBF Manual Proportion/Volume/Direction Compound Valve

| Model | Nominal Diameter(mm) | Nominal Flow(L/min) | Nominal Pressure(MPa) | Safety Valves Pressure Range (MPa) | Handle Operating Force | Mid-position Slide Valve Function |

| CSBF-G20 | 20 | 120 | 25 | 5 – 25 | ≤40 | MOYHKP |

| CSBF-G25 | 25 | 200 | ||||

| CSBF-G32 | 32 | 300 | ||||

| CSBF-G40 | 40 | 450 | ||||

| CSBF-G50 | 50 | 700 | ||||

| CSBF-G65 | 65 | 1200 |

Fault and Troubleshooting for CSBF Manual Proportion/Volume/Direction Compound Valve

| No. | Symptom | Caused Reason | Maintenance Method |

| 1 | Safety valve pressure either low-rise or not low | Ⅰ.The spring is broken /jammed or uninstalled. Ⅱ. The poppet valve’s port is not well sealed. | Ⅰ.The spring is broken /jammed or uninstalled. Ⅱ. The poppet valve’s port is not well sealed. |

| 2 | Pressure compensation device malfunction | Ⅰ.Disassemble for cleaning. Ⅱ.Adjust the spring to make the differential pressure be a nominal rating | Ⅰ.Disassemble for cleaning. Ⅱ.Adjust the spring to make the differential pressure a nominal rating |

| 3 | Ⅰ.The spring is broken /jammed or uninstalled. Ⅱ. The poppet valve’s port is not well sealed. | Dust blocking the valve’s core | Disassemble for cleaning. |

| 4 | Much outside and inside leaking | Ⅰ.Every valve core’s joint frayed. Ⅱ.O type ball seat is broken | Main valve core reversing does not work |

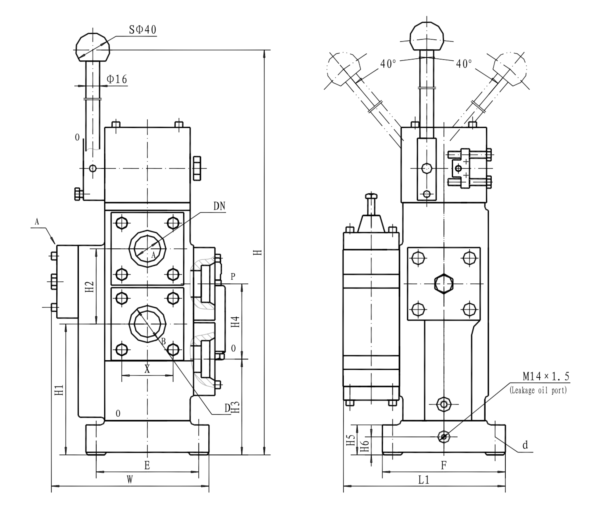

Outline Overall and Installing Dimensions of CSBF Manual Proportion/Volume/Direction Compound Valve

| Drift dia. | Outline overall and installing dimensions | |||||||||||||

| DN | D | X | W | L | F | E | d | H | H1 | H2 | H3 | H4 | H5 | H6 |

| 20 | 27.2 | 45.5 | 150 | 170 | 120 | 100 | 4-φ9 | 445 | 107 | 68 | 77 | 68 | 32 | 19 |

| 25 | 34.5 | 56 | 195 | 202 | 166 | 140 | 4-φ14 | 632 | 138 | 84 | 96 | 84 | 33 | 19 |

| 32 | 43.2 | 60.1 | 192 | 204 | 144 | 120 | 4-φ11 | 635 | 153 | 88 | 112 | 88 | 35 | 21 |

| 40 | 49.5 | 73 | 212 | 223 | 170 | 140 | 4-φ11 | 665 | 160 | 103 | 124 | 103 | 40 | 23 |

| 50 | 62 | 83.4 | 240 | 262 | 180 | 150 | 4-φ13 | 755 | 208 | 124 | 146 | 124 | 45 | 26 |

Slewing Device Matched with CSBF Manual Proportion/Volume/Direction Compound Valve

Slewing device can matches with manual proportion/volume/direction compound valve, and replace the manual to carry out long-distance remote control.

1) Main Technical Parameter

Working Pressure 0.3-1.3Mpa

Output torque 12N·m (when P=1MPa)

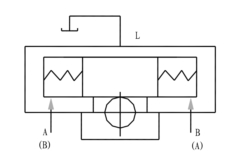

2) Structure and Operating Principle

Function symbol is shown in figure

Slewing device is a piston type rotation hydraulic cylinder, it is consisting of hydraulic cylinder and rotation mechanism. Rotation mechanism is consisting of rack-and-pinion, there’s a piston with a rack in the middle part of the hydraulic cylinder to drive the pinion shaft which mesh with it. when it is working, the control-oil pressure flows into A through shuttle valve, moves piston to do rectilinear motion, rack in the middle of piston to drive gear shaft to rotate, and makes the linked fork swing one angle to make the operating handle of manual proportion/volume/direction compound valve leans an angle to achieve long distance remote control. The return oil in hydraulic cylinder goes back to oil cylinder through B by shuttle valve. On the other hand, operating handle leans to another direction.

3) Outside measurement and installing

Outside measurement shown in figure, when installed, unburden the A side flange of manual proportion/volume/direction compound valve, and install spare flange of slewing device, then install the slewing device.