The Use of Corrosion-resistant Marine Anchors in Harsh Environment

Table of Contents

Marine environments are among the most challenging for engineering materials due to their highly corrosive nature. Constant exposure to saltwater, moisture, temperature fluctuations, and mechanical stresses creates an environment where durability and resistance to corrosion are paramount. Marine anchors, as critical components for securing vessels, offshore structures, and renewable energy platforms, must be designed with advanced corrosion resistance to ensure long-term reliability.

Why Corrosion Resistance Matters for Marine Anchors

Corrosion can significantly weaken the structural integrity of marine anchors, leading to:

- Reduced Holding Power: Compromised anchors may fail to secure vessels, risking drift or accidents.

- Shortened Lifespan: Frequent replacement due to corrosion increases operational costs.

- Increased Maintenance: Ongoing maintenance demands additional time and resources.

- Environmental Impact: Corroded materials can release harmful substances into marine ecosystems.

Corrosion-resistant anchors mitigate these risks, ensuring reliability and sustainability in challenging marine environments.

Materials for Corrosion-resistant Marine Anchors

1. Stainless Steel

- High resistance to pitting and crevice corrosion.

- Suitable for prolonged exposure to seawater.

- Preferred for small to medium-sized anchors.

2. High-Strength Alloys

- Combinations of steel, nickel, and chromium enhance strength and corrosion resistance.

- Widely used in larger, load-bearing anchors.

3. Galvanized Steel

- Coated with a layer of zinc to protect against rust.

- Cost-effective for moderate corrosive conditions.

4. Composite Materials

- Lightweight and inherently resistant to corrosion.

- Emerging as a viable option for specialized applications.

Protective Coatings in Improving Corrosion Resistance of Marin Anchors

- Epoxy Coatings: Provide a robust, water-resistant barrier.

- Hot-Dip Galvanization: Ensures a thick zinc coating for long-lasting protection.

- Thermal Spraying: Applies ceramic or metallic coatings to improve resistance to abrasions and corrosion.

- Passivation: Enhances the natural oxide layer on metals, particularly stainless steel.

- Cathodic Protection: Uses sacrificial anodes to divert corrosion away from the anchor.

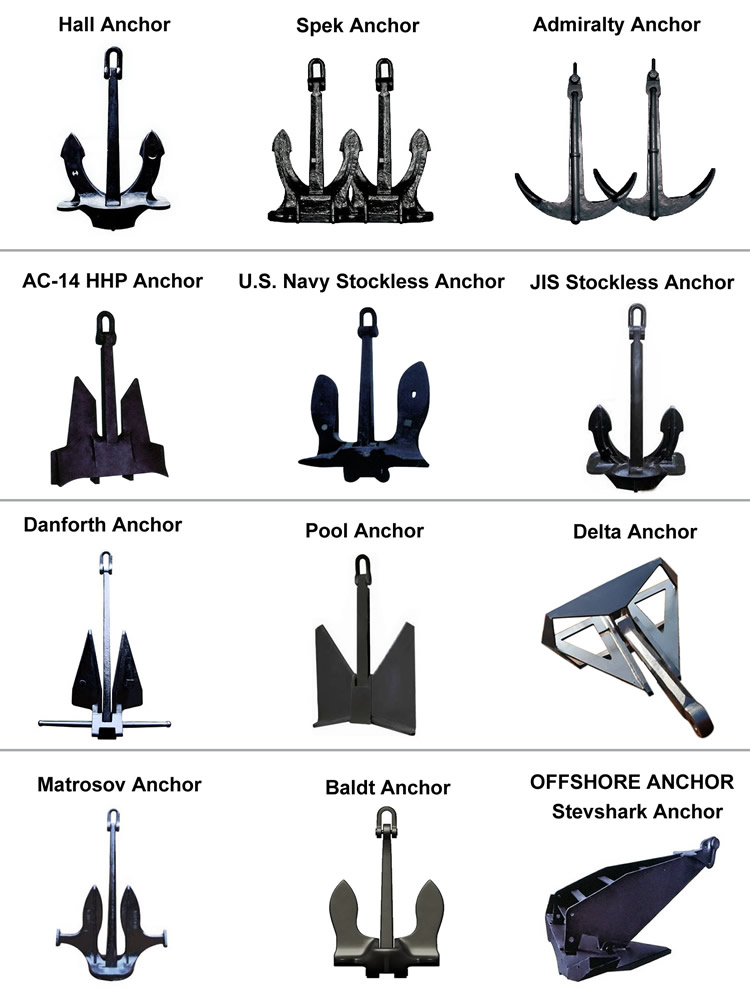

Types of Corrosion-resistant Marine Anchors in Harsh Environment

This chart categorizes corrosion-resistant marine anchors based on their design, strengths, and suitability for harsh environments, aiding in selecting the best anchor for specific maritime applications.

| Anchor Type | Key Features | Applications | Advantages |

| Stockless Anchor | – Compact and easy to handle – High holding power in dense seabeds | Cargo ships, tankers | Space-saving design Easy to deploy |

| Plow Anchor | – Penetrates soft and hard seabeds – Provides excellent holding in currents | Offshore mooring, yachts | Reliable in variable seabed types |

| Fluke/Danforth Anchor | – Lightweight – Excellent holding in sandy or muddy seabeds | Small to medium vessels, emergency anchoring | Lightweight High holding capacity |

| Grapnel Anchor | – Multi-prong design – Best for gripping rocks and uneven surfaces | Small boats, salvage operations | Effective in rocky environments |

| Mushroom Anchor | – Heavy, bowl-shaped design – Long-term holding in soft seabeds | Buoys, floating platforms | Strong holding in mud and sand |

| Drag Embedment Anchor | – Buries into the seabed – High holding power for long-term use | Offshore platforms, renewable energy systems | High holding in soft and cohesive soils |

| Suction Anchor | – Uses suction to secure into seabed – High load-bearing capacity | Offshore wind turbines, oil rigs | Exceptional holding in deepwater applications |

| Pile Anchor | – Driven deep into seabed – Extremely stable | Permanent moorings, large offshore structures | Extremely secure in harsh conditions |

| Deadweight Anchor | – Heavy, simple design – Relies on weight for holding | Temporary moorings, buoys | Simple and reliable |

Challenges and Solutions in Designing Corrosion-Resistant Marine Anchors

Designing corrosion-resistant anchors for marine environments involves overcoming various challenges posed by the harsh conditions of saltwater, seabed interaction, and operational demands. Below are key challenges and potential solutions to address them effectively:

1. Material Selection

Challenge

Marine environments, particularly saltwater and brackish conditions, accelerate material degradation through processes like rust, pitting, and galvanic corrosion. Selecting marine anchor materials that balance cost, durability, and performance is difficult.

Solution

- Use stainless steel or high-performance alloys such as duplex or super duplex stainless steels that resist pitting and crevice corrosion.

- Apply advanced composite materials for lightweight and non-corrosive alternatives, especially for specialized applications.

- Incorporate cathodic protection systems to mitigate galvanic corrosion risks.

2. Protective Coatings

Challenge

Protective coatings are often damaged during anchor handling, deployment, or retrieval, exposing the base material to corrosion.

Solution

- Employ multi-layer coatings, such as epoxy combined with polyurethane, for added durability.

- Use self-healing coatings that repair minor surface abrasions automatically.

- Apply hot-dip galvanization or ceramic-based coatings for heavy-duty anchors exposed to abrasive seabeds.

3. Environmental Variability

Challenge

Marine environments vary widely in terms of salinity, temperature, and seabed composition, making it difficult to design an anchor suitable for all conditions.

Solution

- Conduct site-specific environmental assessments to tailor the anchor material and coating to the specific conditions.

- Use modular anchor designs that allow for interchangeable components, enabling customization based on deployment location.

4. Long-Term Maintenance and Durability

Challenge

Over time, even corrosion-resistant materials and coatings may degrade, necessitating regular maintenance, which can be expensive and time-consuming.

Solution

- Design anchors with embedded sensors to monitor corrosion rates and material integrity in real time.

- Use materials with a longer lifespan, such as titanium alloys, for critical applications despite the higher initial cost.

- Integrate predictive maintenance programs to address issues before they escalate.

5. Cost vs. Performance

Challenge

High-performance materials and coatings significantly increase the initial cost of anchors, which may not be feasible for all applications.

Solution

- Adopt a tiered approach where more expensive materials are used only in the most critical areas of the anchor.

- Explore economical coating technologies, such as thermal spraying, to balance performance with cost.

- Develop innovative manufacturing processes to reduce material waste and overall production costs.

6. Installation and Handling

Challenge

The deployment process can cause mechanical damage to corrosion-resistant coatings, leading to localized corrosion.

Solution

- Implement protective sleeves or shields during transportation and deployment to reduce mechanical wear.

- Design anchors with smooth, impact-resistant surfaces to minimize abrasions during handling.

- Use robotic or automated deployment systems to ensure consistent handling and reduce accidental damage.

7. Environmental Compliance

Challenge

The use of certain materials and coatings may have adverse environmental impacts, leading to regulatory challenges.

Solution

- Transition to eco-friendly coatings that do not leach harmful chemicals into the marine environment.

- Utilize biodegradable materials or recyclable components where feasible.

- Comply with international standards, such as ISO 12944, to ensure environmentally responsible design and production.

Innovations in Corrosion-resistant Marine Anchors

This chart showcases recent innovations in corrosion-resistant marine anchors, highlighting their features, benefits, and ideal applications. These innovations are aimed at improving performance, sustainability, and cost-effectiveness in harsh marine environments.

| Innovation | Description | Benefits | Applications |

| High-Performance Alloys | Use of super duplex stainless steel, titanium, and advanced alloys for better corrosion resistance | Superior protection against stress corrosion, pitting, and crevice corrosion | Offshore platforms, oil rigs, wind farms |

| Self-Healing Coatings | Coatings that repair themselves when damaged or scratched | Reduces maintenance needs and extends anchor lifespan | High abrasion environments, offshore installations |

| Embedded Sensors for Monitoring | Integration of corrosion sensors and IoT technology to monitor anchor conditions in real time | Enables predictive maintenance, reducing unplanned downtime | Offshore wind farms, deep-sea applications |

| Modular Anchor Designs | Anchors with interchangeable parts and customizable components for different seabed conditions | Adaptable to various environments, reducing costs and enhancing performance | Temporary moorings, specialized vessels |

| Eco-Friendly Coatings | Biodegradable or non-toxic coatings that protect anchors while minimizing environmental impact | Sustainable, environmentally responsible, and efficient | Green shipping, eco-conscious installations |

| Additive Manufacturing (3D Printing) | Use of 3D printing to produce complex, customized anchor geometries from corrosion-resistant materials | Reduced production waste and the ability to create optimized designs | Small vessels, specialized applications |

| Hybrid Materials | Combination of traditional materials like steel with corrosion-resistant alloys or composites | Cost-effective, high-performance solution for a variety of environments | Offshore platforms, energy installations |

| Carbon Fiber Reinforced Anchors | Lightweight, corrosion-resistant anchors made with carbon fiber composites | High strength, reduced weight, and resistance to corrosion | Yachts, recreational vessels |

| Suction-Based Anchors | Anchors using suction to embed into the seabed, designed for long-term holding in soft soils | Enhanced holding power with minimal seabed disruption | Offshore wind farms, deep-water platforms |

| Ceramic-Coated Anchors | Steel anchors with a protective ceramic coating to prevent corrosion and abrasion | Increased resistance to abrasive seabeds and corrosion | Heavy-duty marine vessels, offshore construction |

Summary

Corrosion-resistant marine anchors are vital for ensuring the safety, efficiency, and sustainability of maritime operations in harsh environments. Innovations in materials, coatings, and design are paving the way for anchors that can withstand the most demanding conditions while minimizing environmental impact.