The Critical Role of Deck Machinery in Marine Operations

Deck machinery is pivotal in marine operations, enabling ships to anchor, moor, handle cargo, and navigate efficiently. These mechanical systems provide the necessary power and control for various onboard activities, ensuring safety and operational effectiveness in both commercial and offshore maritime industries. With advancements in technology, modern deck machinery has become more automated, durable, and energy-efficient, improving the overall performance of vessels.

Table of Contents

Key Functions of Deck Machinery

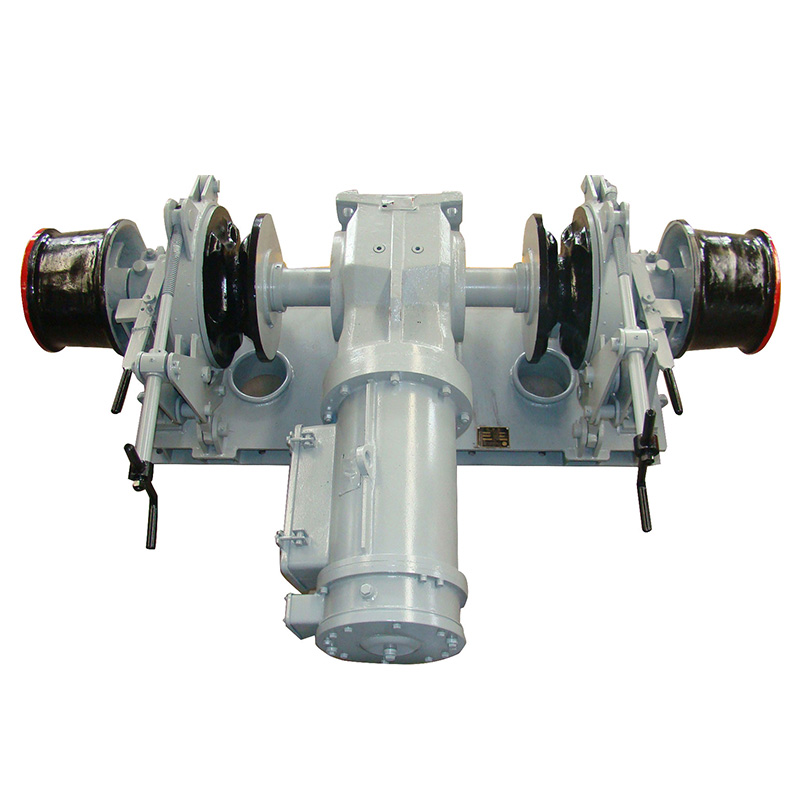

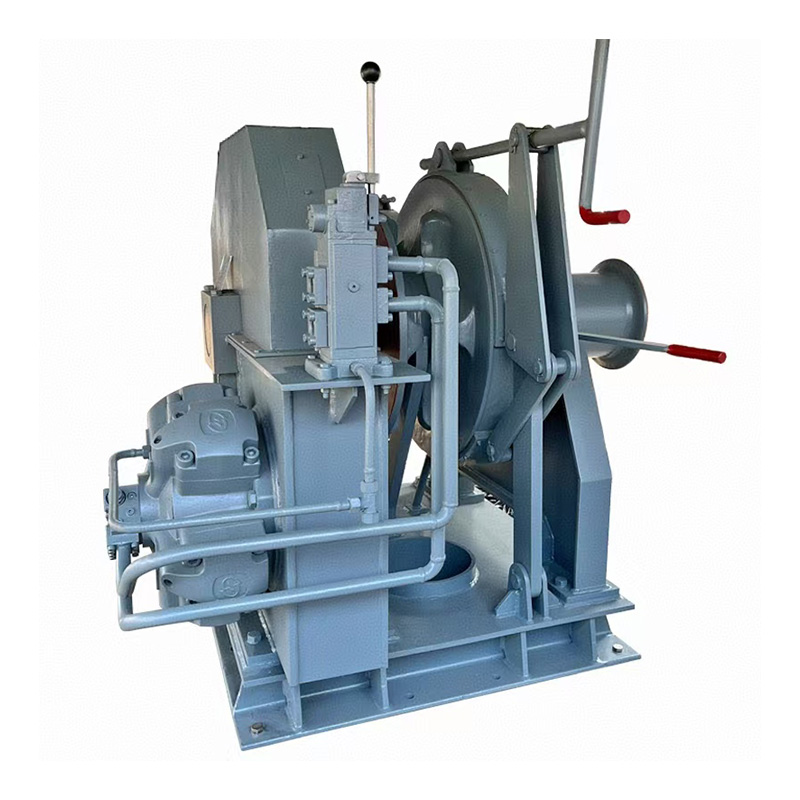

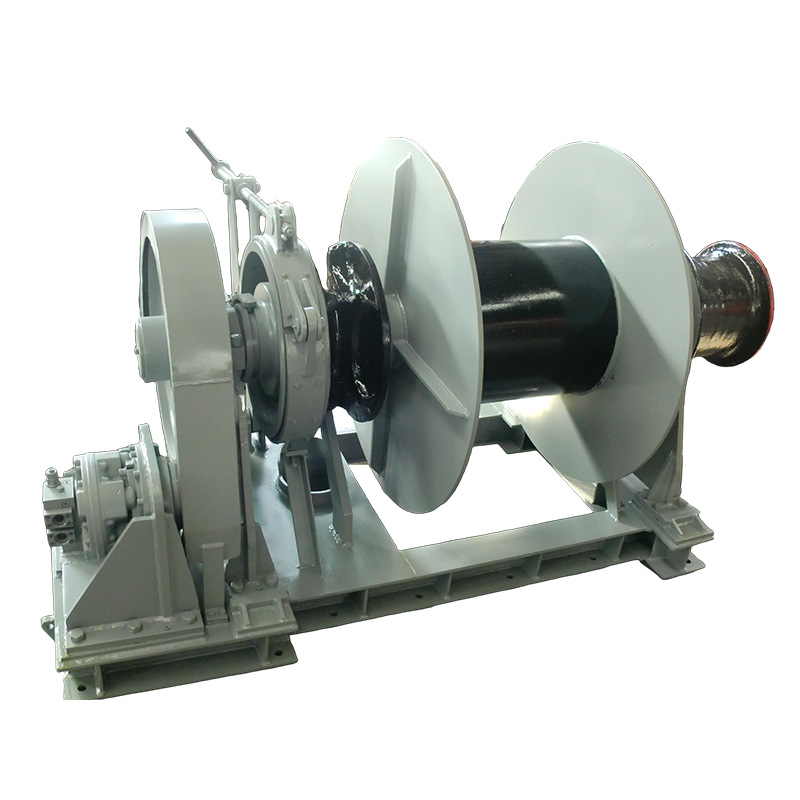

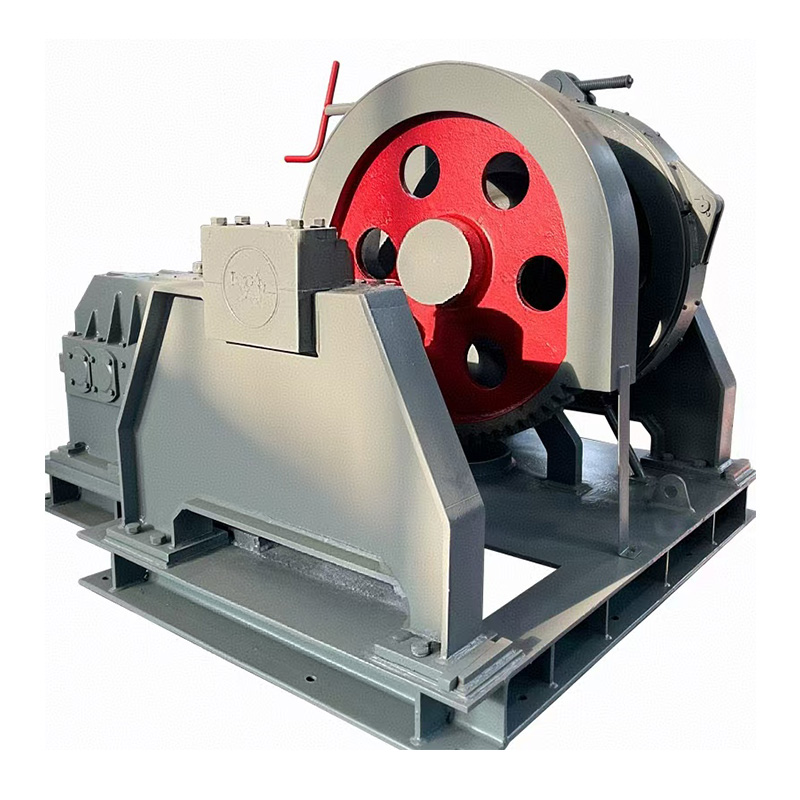

Deck machinery is essential for multiple marine operations. Anchoring and mooring are fundamental functions, where equipment like windlasses and mooring winches help secure vessels safely in harbors or offshore locations. Cargo handling systems, including deck cranes and hatch covers, facilitate efficient loading and unloading of goods, ensuring smooth logistics for shipping operations. Ship maneuverability also depends on critical deck machinery, such as steering gear systems, which allow vessels to navigate through different sea conditions with precision.

Types of Deck Machinery in Marine Operations

This chart provides an overview of key deck machinery types, their functions, and their roles in marine operations. Each piece of equipment contributes to the overall efficiency and safety of ships and offshore structures.

| Type of Deck Machinery | Function | Common Applications |

| Winches | Used for pulling, lifting, and tensioning ropes or cables | Mooring winch, towing winch, and anchoring which |

| Windlasses | Raises and lowers anchor chains | Anchor handling and securing vessels |

| Capstans | Handles ropes and cables with a vertical-axis design | Mooring, warping, and docking assistance |

| Deck Cranes | Lifts and transfers cargo between ships and ports | Cargo handling on container ships, bulk carriers, and offshore vessels |

| Davits | Davits for Launches and retrieves lifeboats | Emergency evacuations and life-saving operations |

| Steering Gear Systems | Controls the movement of the ship’s rudder | Navigation and maneuvering in different sea conditions |

| Hydraulic Power Units (HPUs) | Supplies hydraulic pressure for deck machinery | Powers winches, windlasses, steering systems, and cranes |

| Hatch Covers | Seals cargo holds to protect goods from external elements | Used on bulk carriers, container ships, and general cargo vessels |

| Towing Equipment | Provides towing capabilities for assisting other vessels | Tugboats, salvage operations, and offshore support vessels |

| Anchor Handling Systems | Manages the deployment and retrieval of anchors | Offshore supply vessels, anchor-handling tugboats |

Technological Advancements in Deck Machinery

1. Automation and Smart Control Systems

Modern deck machinery is increasingly integrated with automation and remote-control capabilities, reducing the need for manual operations. Digital control panels, programmable logic controllers (PLCs), and IoT-enabled systems allow real-time monitoring and adjustment of equipment such as winches, windlasses, and cranes. This automation enhances precision, reduces human error, and improves operational efficiency.

2. Electric-Powered Deck Machinery

The shift from hydraulic to electric-powered deck machinery is gaining momentum due to its energy efficiency, lower maintenance requirements, and reduced environmental impact. Electric winches, cranes, and capstans eliminate the risks associated with hydraulic oil leaks and provide smoother operation with precise torque control.

3. High-strength and Corrosion-Resistant Materials

Advanced materials such as high-strength steel, composite coatings, and corrosion-resistant alloys have improved the durability and longevity of deck machinery. These materials enhance resistance to harsh marine environments, reducing maintenance costs and extending service life.

4. Condition Monitoring and Predictive Maintenance

Smart sensors and data analytics are now embedded in deck machinery to enable real-time condition monitoring. Vibration analysis, load monitoring, and temperature sensors help detect early signs of wear and potential failures. Predictive maintenance systems use AI-driven analytics to schedule repairs before breakdowns occur, minimizing downtime and operational disruptions.

5. Improved Safety Features

Modern deck machinery incorporates enhanced safety mechanisms such as emergency stop systems, overload protection, and automated braking. These features prevent accidents, improve crew safety, and ensure compliance with international maritime safety regulations.

6. Integration with Digital Ship Systems

Deck machinery is now being integrated into ship-wide digital ecosystems. Data from winches, cranes, and steering systems can be synchronized with onboard navigation and automation systems. This integration enables better coordination, optimized power usage, and enhanced overall vessel performance.

7. Energy-Efficient and Eco-Friendly Solutions

With increasing focus on sustainability, energy-efficient deck machinery designs are being developed to reduce fuel consumption and emissions. Regenerative energy recovery systems in electric winches and cranes allow power to be reused, reducing overall energy demands on the vessel.

Key Factors to Consider for Choosing the Right Type of Deck Machinery

This chart provides a structured approach to selecting the right deck machinery, ensuring optimal performance, safety, and efficiency in marine operations.

| Factor | Description | Importance |

| Vessel Type | Different ships require specific deck machinery based on their operations, such as cargo ships needing cranes or offshore vessels requiring winches. | Ensures compatibility with vessel functions. |

| Operational Requirements | The machinery must meet specific needs like mooring, towing, anchoring, or cargo handling. | Enhances efficiency and functionality. |

| Load Capacity | The equipment should handle the required load safely and efficiently. | Prevents overloading and ensures safety. |

| Power Source | Machinery can be electric, hydraulic, or pneumatic, depending on the ship’s power system. | Affects energy efficiency and maintenance needs. |

| Durability and Corrosion Resistance | Materials should withstand harsh marine conditions, such as saltwater and extreme weather. | Increases lifespan and reduces maintenance costs. |

| Automation and Control Features | Advanced systems with remote control, IoT integration, and automation improve operations. | Enhances precision, reduces manual effort, and boosts safety. |

| Compliance with Regulations | Machinery must adhere to maritime safety and environmental standards. | Ensures legal operation and prevents penalties. |

| Maintenance and Repair Needs | Easily serviceable machinery with available spare parts reduces downtime. | Lowers operational costs and improves reliability. |

| Safety Features | Emergency stop functions, overload protection, and automated braking enhance safety. | Protects crew members and prevents accidents. |

| Cost vs. Long-Term Investment | The initial cost should be balanced with durability, efficiency, and lifecycle costs. | Ensures cost-effectiveness over time. |

Summary

Deck machinery is vital for marine operations, supporting the functions, such as anchoring, mooring, cargo handling, steering, etc. From anchoring and mooring to cargo handling and navigation, it can ensure the smooth maritime activities. As the industry moves toward automation and sustainability, advancements in deck machinery continue to enhance operational performance, making modern vessels more efficient and reliable in demanding marine environments.