How to Maintain Deck Machinery Effectively

Deck machinery is crucial for the safe and efficient operation of ships. Proper maintenance ensures that equipment functions efficiently, reducing the risk of unexpected failures, and extending the lifespan of essential components. This article provides a comprehensive guide on how to maintain deck machinery effectively.

Table of Contents

What is Deck Machinery

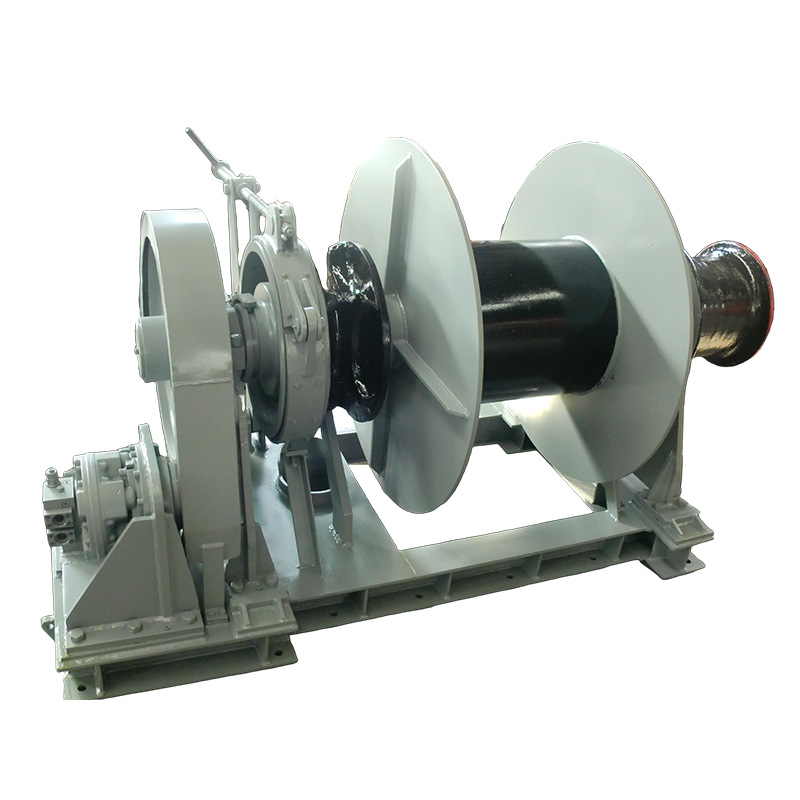

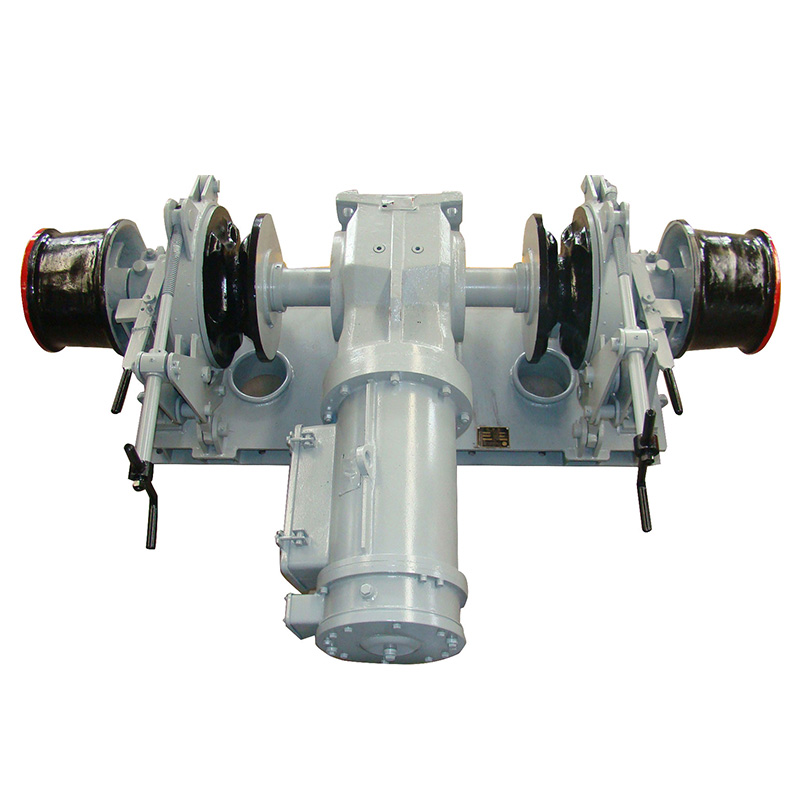

Deck machinery refers to the mechanical and hydraulic equipment installed on a ship’s deck, used for anchoring, mooring, cargo handling, and towing operations. It includes winches, windlasses, capstans, cranes, davits, and hydraulic systems that facilitate essential maritime tasks. Properly functioning deck machinery ensures safe and efficient vessel operations, reducing risks during docking, cargo transfer, and emergency situations.

Why Maintaining Deck Machinery is Necessary

This chart highlights the importance of maintaining deck machinery for operational, financial, and safety reasons.

| Reason | Explanation |

| Ensures Operational Efficiency | Regular maintenance keeps machinery running smoothly, reducing delays and improving productivity. |

| Prevents Equipment Failure | Identifying and fixing issues early avoids unexpected breakdowns during critical operations. |

| Enhances Safety | Well-maintained machinery reduces the risk of accidents, protecting crew and cargo. |

| Extends Equipment Lifespan | Proper care minimizes wear and tear, prolonging the life of expensive machinery. |

| Reduces Repair Costs | Preventive maintenance is cheaper than emergency repairs or replacements. |

| Maintains Compliance | Regular upkeep ensures adherence to maritime regulations and industry standards. |

| Improves Reliability | Reliable machinery ensures consistent performance, even in harsh conditions. |

| Prevents Corrosion and Damage | Cleaning and lubrication protect against saltwater, rust, and environmental damage. |

| Minimizes Downtime | Scheduled maintenance reduces the likelihood of unplanned operational interruptions. |

| Protects Cargo and Vessel | Properly functioning deck machinery ensures safe handling of cargo and prevents damage to the vessel. |

Best Practices for Maintaining Deck Machinery

1. Regular Inspections

Routine inspections are fundamental to identifying potential issues before they become major problems. Conducting visual checks allows operators to spot early signs of wear, misalignment, or leaks. Unusual noises, excessive vibrations, or overheating may indicate mechanical faults that require immediate attention. Additionally, examining structural components, fasteners, and load-bearing elements ensures that all parts remain in optimal condition. By addressing minor issues early, ship operators can prevent costly breakdowns and maintain the reliability of deck machinery.

2. Lubrication and Friction Control

Proper lubrication is essential to reducing friction and preventing premature wear on moving parts. Bearings, gears, and chains require the application of manufacturer-recommended lubricants to maintain smooth operation. Over time, lubricants can become contaminated, losing their effectiveness and leading to increased wear. Regularly monitoring and replenishing lubricants prevents unnecessary strain on mechanical components. In addition to improving efficiency, lubrication acts as a protective barrier against corrosion, particularly in harsh marine environments.

3. Hydraulic System Maintenance

Hydraulic systems power many deck machinery components, including winches, cranes, and capstans. These systems require constant monitoring to ensure efficiency and prevent unexpected failures. Checking hydraulic fluid levels, inspecting hoses for leaks or cracks, and replacing worn seals are essential maintenance practices. Air trapped in hydraulic systems can cause pressure fluctuations, reducing performance and potentially leading to system failure. Keeping hydraulic components in top condition ensures the smooth operation of deck machinery and prevents costly repairs.

4. Protecting Machinery from Corrosion

Saltwater exposure makes corrosion one of the biggest challenges in maintaining deck machinery. Without proper protection, metal components can deteriorate quickly, leading to compromised structural integrity and mechanical failure. Applying anti-corrosion coatings, marine-grade paints, and protective sealants helps shield equipment from rust. Regularly washing machinery with fresh water removes accumulated salt, reducing the risk of corrosion. Additionally, using stainless steel or galvanized components in critical areas enhances durability and resistance to harsh environmental conditions.

5. Ensuring Electrical System Reliability

Modern deck machinery integrates electrical systems for automation and control, making electrical maintenance a critical aspect of overall upkeep. Moisture accumulation, corroded terminals, and damaged wiring can lead to electrical malfunctions or even hazardous situations. Regularly inspecting electrical connections, ensuring proper grounding, and keeping control panels dry are essential steps in maintaining reliability. By addressing electrical issues proactively, operators can avoid unexpected failures that could disrupt operations.

6. Brake and Clutch System Maintenance

Brakes and clutches are essential for controlling winches, windlasses, and other load-handling equipment. Over time, brake linings and clutch plates wear down, requiring periodic inspection and adjustment. Proper tension settings ensure smooth engagement and prevent uncontrolled movement of loads. If components become excessively worn, timely replacements are necessary to maintain operational safety. Ensuring that these systems function properly is crucial for preventing accidents and maintaining overall machinery performance.

7. Performance Testing and Calibration

Regular performance testing helps verify that deck machinery operates within safe and efficient limits. Conducting load tests under both no-load and full-load conditions ensures that equipment can handle operational demands. Calibration of load sensors and safety mechanisms helps maintain accuracy in automated systems. Identifying and correcting performance irregularities early reduces the risk of operational failures, improving the reliability of deck machinery.

8. Training and Record-Keeping for Long-Term Maintenance

A well-trained crew is essential for the successful maintenance of deck machinery. Providing ongoing training on operational procedures, troubleshooting techniques, and preventive maintenance enhances efficiency and reduces human error. Keeping detailed maintenance records allows operators to track servicing schedules, identify recurring issues, and ensure compliance with industry regulations. Proper documentation also helps streamline future repairs and replacements, ensuring that machinery remains in optimal condition.

Summary

Maintaining deck machinery is a continuous process that requires attention to detail, proactive care, and adherence to best practices. Through conducting regular inspections, ensuring proper lubrication, maintaining hydraulic and electrical systems, preventing corrosion, and prioritizing crew training, ship operators can enhance the reliability and longevity of their equipment. A well-maintained deck machinery system not only improves operational efficiency but also ensures safety and reduces the risk of costly breakdowns.