How to Design Marine Anchor Winches for Harsh Weather Conditions

In harsh weather environments, marine anchor winches must be designed to withstand extreme winds, high waves, freezing temperatures, and corrosive seawater. Achieving a reliable and durable anchor winch requires the right combination of materials, sealing techniques, motor efficiency, and safety features. This article focus on the topic of how to design marine anchor winches, highlighting the key design considerations for anchor winches in harsh weather conditions.

Table of Contents

What are the Functions of Marine Anchor Winches

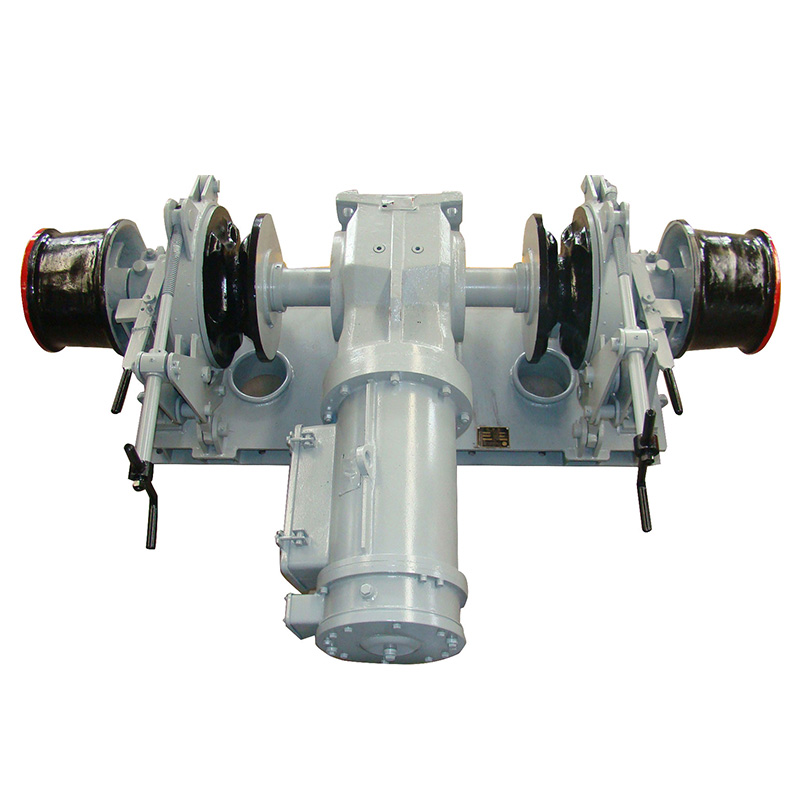

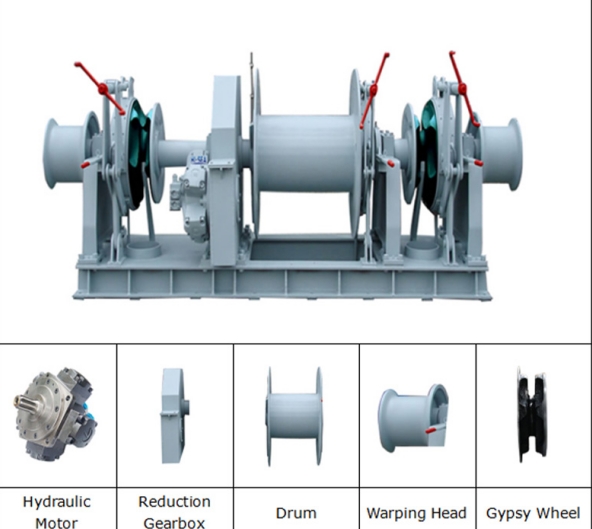

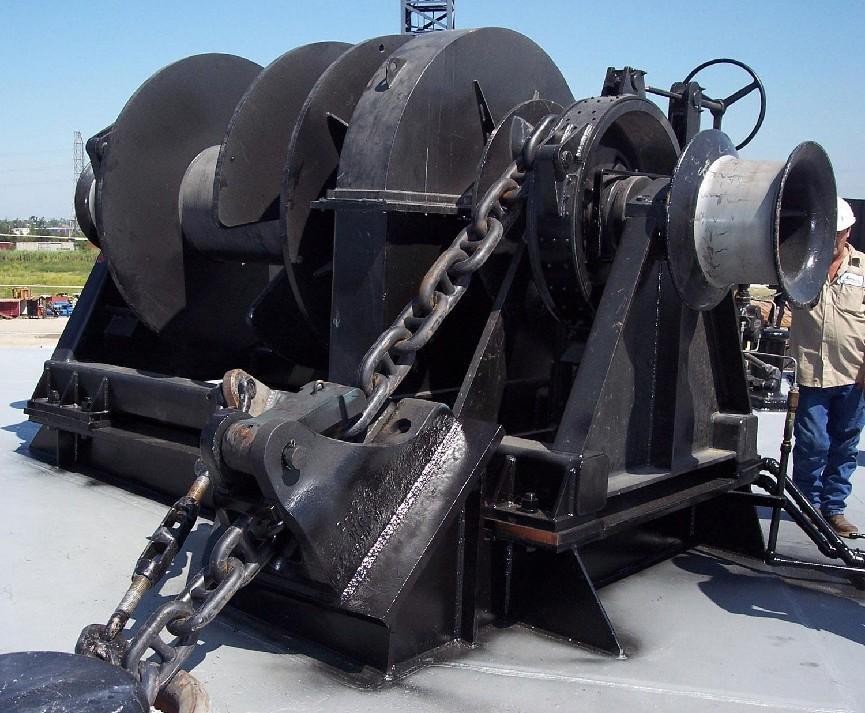

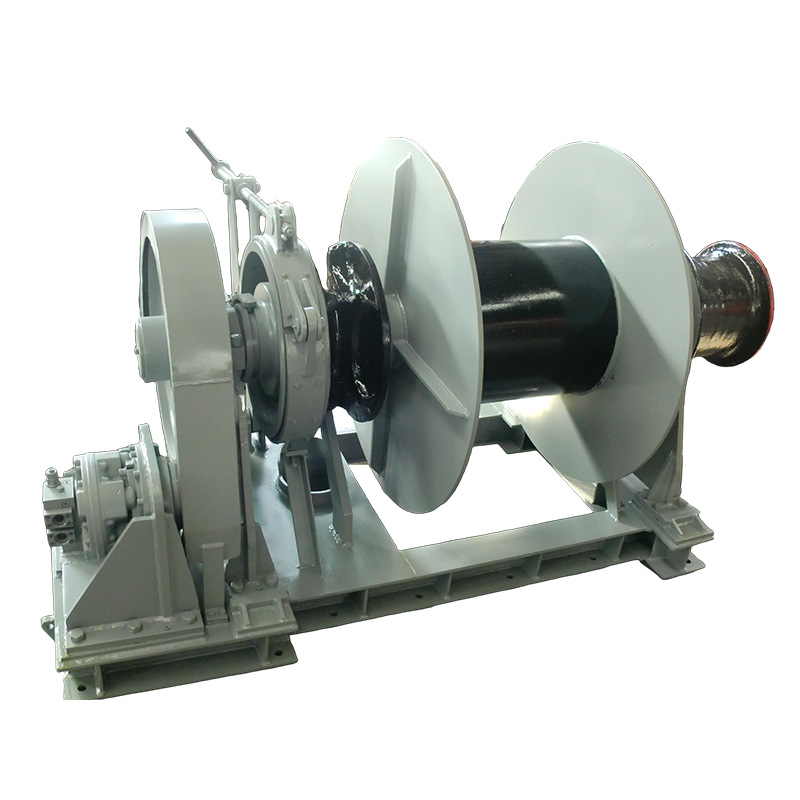

A marine anchor winch is a mechanical device used on ships and offshore platforms to deploy, retrieve, and secure the anchor. It consists of a motorized or manual winding system that controls the anchor chain or rope, ensuring precise positioning and stability of the vessel. Designed to withstand harsh marine environments, anchor winches are typically made from corrosion-resistant materials and feature robust braking and tension control systems. They can be powered by hydraulic, electric, or manual mechanisms, depending on the vessel’s size and operational needs.

Challenges of Marine Anchor Winches in Harsh Weather Conditions

| Challenges | Description |

| Corrosion and Rust | Constant exposure to saltwater accelerates material degradation. |

| Insufficient Load Capacity | High winds and rough seas increase strain on the winch. |

| Water Ingress | Moisture can damage electrical and mechanical components. |

| Freezing and Ice Accumulation | Cold weather can freeze hydraulic systems and mechanical parts. |

| Operational Instability | High waves and vessel movement can cause anchor slippage. |

| Excessive Vibration and Shock | Rough seas create high impact forces on the winch system. |

| Difficult Maintenance | Harsh weather increases wear and tear, requiring frequent inspections. |

| Electrical Failures | Wet conditions and extreme temperatures affect electrical circuits. |

| Manual Handling Risks | Rough weather makes manual operation dangerous. |

Key Factors to Consider for Designing Marine Anchor Winches in Harsh Weather Conditions

1. Material Selection for Corrosion Resistance

Marine environments are highly corrosive due to constant exposure to seawater, humidity, and salt-laden air. The choice of materials plays a crucial role in ensuring the longevity and durability of anchor winches.

- Stainless Steel (316 or Duplex): Offers high corrosion resistance and strength.

- Galvanized Steel: Provides a protective zinc coating to resist rust.

- Marine-Grade Aluminum: Lightweight and corrosion-resistant, ideal for smaller vessels.

- Protective Coatings: Epoxy coatings, hot-dip galvanization, or specialized marine paints add extra protection.

2. Sealing and Waterproofing Features

Water ingress is a common issue in marine equipment operating under extreme weather conditions. Proper sealing is necessary to prevent moisture from entering critical components such as motors, gears, and control panels. IP67 or higher-rated enclosures should be used to protect electrical and mechanical parts from water and dust. Additionally, rubber gaskets and marine-grade sealing compounds help ensure that all openings, joints, and housings remain watertight.

3. High-Performance Motor and Drive Systems

The motor and drive system must be capable of handling sudden load variations caused by strong currents, ice buildup, or wind forces. Hydraulic motors are often preferred for heavy-duty marine applications due to their ability to deliver high torque and withstand extreme loads. Alternatively, electric winches with variable frequency drives (VFDs) provide precise control, reduced energy consumption, and smoother operation. In cold-weather environments, motor systems should include anti-freezing heaters to prevent damage from low temperatures.

4. Load Management and Tension Control

Unpredictable sea conditions require anchor winches to have automated tension control systems that adjust winch speed and braking force in response to environmental changes. Dynamic load monitoring sensors help prevent excessive strain on the winch mechanism by automatically adjusting tension based on wave and current forces. Incorporating self-tensioning capabilities allows the winch to compensate for fluctuations in anchor chain loads, reducing wear and increasing system reliability.

5. Robust Braking Systems

Braking is critical in preventing anchor slippage during storms or rough waters. Marine anchor winches should be equipped with multi-disc fail-safe brakes that automatically engage if power is lost. Hydraulic or electromagnetic braking systems provide an additional layer of safety by ensuring immediate stopping power in emergency situations. For vessels operating in icy conditions, anti-freeze brake fluids and heating elements can prevent brake failure due to freezing temperatures.

6. Remote Control and Automation

Advanced automation and remote control capabilities improve both safety and efficiency in anchor winch operations. Wireless control systems allow crew members to operate the winch from a safe distance, reducing exposure to extreme weather conditions. Additionally, integrating IoT (Internet of Things) sensors enables real-time monitoring of performance metrics such as load, temperature, and motor efficiency. Automated diagnostics and predictive maintenance alerts help reduce downtime and improve overall operational reliability.

7. Shock Absorption and Vibration Resistance

Harsh weather can create extreme vibrations and shock loads that affect winch performance and lifespan. To mitigate these effects, winches should incorporate shock-absorbing mounts, reinforced gear housings, and anti-vibration materials. Using torsional dampers in the drive system helps absorb energy from sudden movements, preventing damage to mechanical components.

8. Energy Efficiency and Power Backup

Designing energy-efficient anchor winches reduces fuel consumption and extends operational lifespan. Regenerative braking systems can recover energy during anchor retrieval, lowering overall power demand. Additionally, vessels operating in remote locations should have backup power sources, such as redundant battery packs or auxiliary hydraulic systems, to ensure continuous operation during electrical failures or emergencies.

Summary

Designing a marine anchor winch for harsh weather conditions requires a combination of corrosion-resistant materials, high-powered motors, waterproofing, low-temperature protection, automated controls, and shock resistance. Through incorporating these elements, manufacturers can ensure reliability, safety, and longevity of anchor winches in the most demanding marine environments.