How to Choose the Right Mooring Bollards for Different Docking Application

Mooring bollards are used in securing vessels at docks, ensuring stability, safety, and efficiency in maritime operations. Choosing the right type of mooring bollard is essential, as different docking environments, vessel sizes, and operational demands require specific bollard designs and load capacities. Understanding the factors that influence marine bollard selection can help prevent mooring failures and enhance overall dock safety.

Understanding the Functions of Mooring Bollards

Mooring bollards are essential fixtures in docking facilities, providing secure anchoring points for mooring lines to keep vessels safely in place. Designed to withstand significant tension forces from ships, these marine bollards come in various shapes and sizes, each suited for specific maritime applications. Factors like load capacity, environmental conditions, and mooring configurations influence the choice of marine mooring bollard. Proper selection and maintenance ensure efficient mooring operations, enhancing safety and stability in ports, marinas, and industrial docks.

Common Types of Mooring Bollards

Mooring bollards come in various designs, each suited to specific docking applications.

| Bollard Type | Description | Typical Applications |

| Pillar Bollard | A simple, cylindrical bollard allowing mooring lines to be secured from various angles. | General-purpose mooring in marinas and small docks. |

| Tee Bollard | T-shaped bollard offering high load-bearing capacity and strong mooring support. | Commercial ports and industrial terminals handling large vessels. |

| Horn Bollard | Features two curved “horns” to facilitate secure line management and quick release. | Ferry terminals and areas requiring frequent mooring/unmooring. |

| Kidney Bollard | Compact, kidney-shaped bollard designed for tight spaces while providing strong mooring. | Small docks and space-constrained port facilities. |

| Single Bitt Bollard | A single-post bollard designed for high-tension mooring with heavy-duty rope handling. | Industrial docks and cargo terminals. |

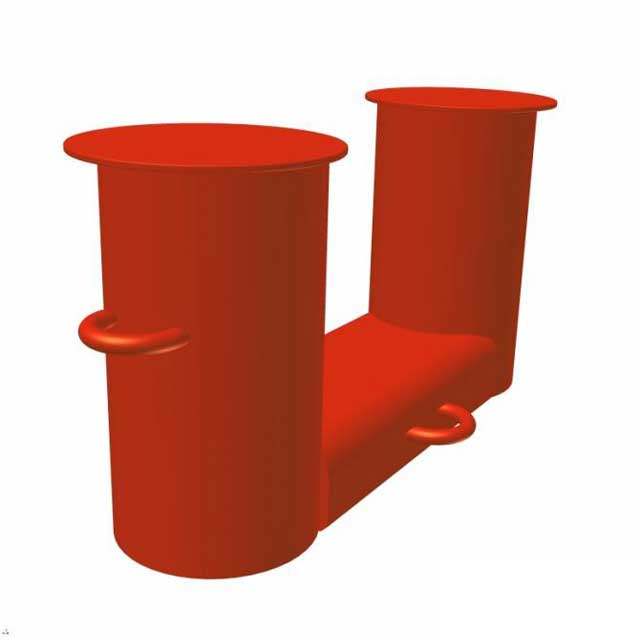

| Double Bitt Bollard | Consists of two vertical posts, allowing multiple mooring lines to be secured under high tension. | Large commercial ports and bulk cargo terminals. |

Key Factors to Consider for Choosing the Right Mooring Bollard

1. Load Capacity and Mooring Forces

The most crucial factor in selecting a mooring bollard is its load capacity, which determines how much force it can withstand. Mooring forces depend on the size and weight of the vessel, as well as external environmental factors such as wind, currents, waves, and tides.

For large cargo ships, tankers, or container vessels, high-capacity bollards such as tee bollards or double bitt bollards are necessary to handle strong mooring forces. Smaller vessels, such as leisure boats or ferries, require bollards with lower load ratings, such as pillar bollards or kidney bollards. Choosing a bollard with the appropriate load-bearing capacity prevents structural failures, ensuring vessel stability and operational safety.

2. Dock Layout and Space Constraints

The physical layout of the dock or port greatly influences the type and size of the bollard that can be installed. Some docks have limited space, requiring compact bollards like kidney bollards, while larger ports can accommodate a variety of bollard designs, such as horn or tee bollards, which allow for multiple line angles.

The placement of the bollards is also essential. Proper positioning ensures efficient mooring and unmooring, preventing excessive line stress and minimizing vessel movement. Additionally, docks with high tidal variations may need bollards positioned at different heights to accommodate changes in water levels.

3. Mooring Line Configuration and Vessel Type

Different vessel types have varying mooring requirements, affecting the choice of bollard. Some vessels require multiple mooring points at different angles, while others use a single, high-tension mooring line.

- Horn and tee bollards provide flexibility for securing multiple mooring lines at different angles, making them suitable for commercial ports and ferry terminals.

- Single and double bitt bollards are ideal for heavy-duty applications where high-tension mooring lines are used, such as industrial terminals handling large cargo ships.

- Pillar bollards are commonly used in marinas and smaller docks where vessels require straightforward, low-tension mooring.

Selecting the correct marine mooring bollard design ensures that mooring lines are effectively secured without causing excessive strain on the ropes or dock structure.

4. Material and Corrosion Resistance

Since mooring bollards are constantly exposed to harsh marine environments, the material and protective coatings used play a significant role in their durability and maintenance requirements. Most bollards are made from:

- Cast steel: High strength and durability, commonly used for heavy-duty applications.

- Ductile iron: Offers good tensile strength and impact resistance.

- Cast iron: Cost-effective but requires protective coatings for corrosion resistance.

To extend the lifespan of the bollard, protective coatings such as galvanization, epoxy coatings, or anti-corrosion paint should be applied. Ports with high salinity and humidity must invest in high-quality, corrosion-resistant marine mooring bollards to reduce long-term maintenance costs.

5. Safety Considerations

Safety is a critical aspect of bollard selection. The bollard must be properly rated for its intended load and securely anchored to withstand extreme mooring forces. Poorly installed or undersized bollards can lead to failures, resulting in vessel damage, personal injury, and costly repairs.

Other safety considerations include:

- Smooth edges and proper surface finishing to minimize wear and tear on mooring lines.

- Adequate spacing between bollards to prevent entanglement of ropes.

- Periodic inspections and maintenance to check for structural integrity and corrosion.

Investing in the right bollard and maintaining it properly ensures long-term safety and operational efficiency.

6. Environmental and Operational Conditions

The environmental conditions of the docking site influence bollard selection. Ports exposed to strong winds, tidal variations, or ice formation may require bollards with higher strength and special coatings. Additionally, high-traffic docking areas require bollards that can handle frequent mooring and unmooring, making durability a key factor.

In locations with extreme weather conditions, bollards should be reinforced and regularly inspected to ensure they remain in optimal working condition.

Specific Mooring Bollard Types for Different Docking Applications

| Docking Application | Recommended Mooring Bollard Type | Reason for Selection |

| Commercial Ports | Tee Bollard, Double Bitt Bollard | High load capacity to secure large cargo ships and tankers. |

| Industrial Terminals | Single Bitt Bollard, Horn Bollard | Handles high-tension mooring for bulk carriers and heavy-duty vessels. |

| Ferry Terminals | Horn Bollard, Tee Bollard | Allows quick mooring and unmooring for frequent docking operations. |

| Marinas & Recreational Docks | Pillar Bollard, Kidney Bollard | Suitable for smaller boats, providing flexible mooring in limited spaces. |

| Container Terminals | Double Bitt Bollard, Tee Bollard | Supports multiple mooring lines under heavy loads for large container ships. |

| Space-Constrained Docks | Kidney Bollard, Pillar Bollard | Compact design allows efficient mooring in confined docking areas. |

Summary

Choosing the right mooring bollard for different docking applications requires careful consideration of vessel size, mooring loads, environmental conditions, and safety requirements. By selecting the appropriate bollard type, ports and docking facilities can ensure reliable mooring operations, minimize maintenance costs, and enhance overall safety. Proper installation and regular inspections further contribute to the longevity and effectiveness of mooring bollards, ensuring seamless docking operations across various marine environments.