What Is The Roller Fairlead And How To Select The Best Manufacturer

Fairlead refers to the general name of the various devices which guide, limit, or change the direction and position of the cable without damaging the cable. Roller fairlead is one of the most widely used fairleads and is an important part of the marine mooring device.

Important Marine Mooring Device – Roller Fairlead

The Constitute Of Roller Fairlead

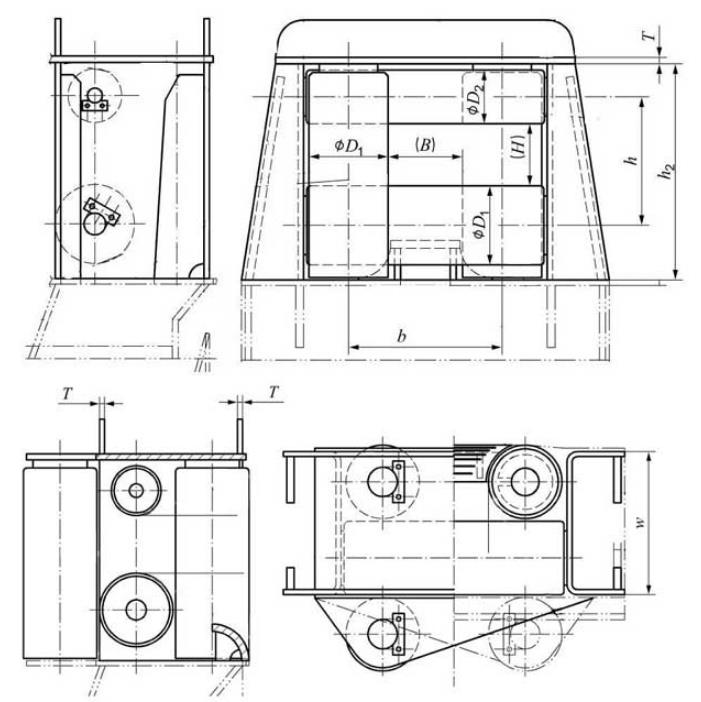

The roller fairlead is consisting of vertical rollers and horizontal rollers, which are replaced with a roller cable and have added a horizontal roller. It can direct cables from all directions can be guided. In addition to commonly used four-rolled fairlead, there are types of three rollers, five rollers, six rollers, seven rollers and nine rollers.

The warping roller fairlead is made of several independent rollers, closed and open, according to the number of separate rollers, the types of double rollers, three rollers, and four rollers are widely used. It can simultaneously derive the root cable, mostly used in large and medium-sized ships.

Important Role For Marine Mooring Device

The roller fairlead is suitable for the mooring of the engineering ship and the strait waterway with multi-directional conductors. There are also a relatively large roller fairlead that allows the ambulance person to transport the wounded person from here when there is an accident. The function of the roller fairlead is related to the normal navigation of the ship and the efficiency of the treatment personnel, even related to the life safety of the ship.

Working Principle Of Roller Fairlead

One basic working cycle of the roller fairlead is divided into five processes including intake, compression, combustion, expansion, exhaust.

When the roller works, the piston is moved back and forth in the cylinder, and this motion is converted to the crankshaft rotation motion by the crank link mechanism. The top of the piston movement in the cylinder is called a dead center, and the lowest position of the cylinder achieved by the movement is referred to as a stopping point. The piston from the dead point to the stop point becomes a stroke. Every turn in the crankshaft, the piston has two strokes.

The working system of the fairlead mainly includes roller cooling, roller lubrication, and fuel system.

1.Cooling System

The system is divided into freshwater cooling systems, seawater cooling systems, and central cooling systems. In order to spread this heat, the cooling liquid is used to continuously flow through the thermal member.

2. Lubrication System

The system includes lubrication, cooling, cleaning, sealing, corrosion, reducing noise.

3. Fuel system

The system mainly includes fuel installation, storage, dismissal, purification, heat, etc. The heating equipment to maintain heavy oil in the oil tank for maintaining the fluidity of heavy oil. Heavy oil should be purified and atomized by purification and atomization before transporting the roller fairlead high-pressure oil pump.

Installation Precautions For Roller Fairlead

For the installation of the roller fairlead, what should be paid attention to?

1.Safety

It is necessary to pay attention to safety, although the device is not flammable, the safety environmental requirements should meet.

2. Environment

It is necessary to pay attention to avoiding environmental moisture and ensure that the environment has been in a dry state, avoiding rust in the process of installation.

3. Packaging

In the packaging requirements, it is to ensure excellent functions, extending the service life.

Maintenance Of Roller Fairlead

The roller fairlead is always exposed. If it is not well maintained in use, it will increase the chance of damage in use. The maintenance work is needed. So, how does the maintenance work do? Here are some instructions.

Anti-rust Work

For roller fairlead, made with stainless steel materials, people should apply a certain anti-rust oil on its surface before use, and reduce the rust chance in use through anti-rust oil, to ensure a good appearance.

Checking Work

Each component of roller fairlead is needed to be checked for daily use. For any small problem in the check, it is necessary to be paid attention and solve it, which will reduce the chances of damaging for ensuring the long-term service life.

Preventing Deformation

The deformation will affect the use. If the deformation is serious, it will directly lead to the occurrence of fracture. So in the applications,can prevent it from deforming through the control of the pressure.

Daily maintenance can ensure the normal use of roller fairlead, guaranteeing the good effect.

How To Select The Best Roller Fairlead Manufacturer

Roller fairlead has a very important role in the marine industry. To ensure good performance, how to choose the high-quality products from the best roller fairlead manufacturer and what factors should be considered are important?

1. Appearance

The material quality, structure, processing level of a roller fairlead, can be reflected from the appearance.

In terms of the reliability of the roller fairlead, it is very important that there are no defects in the appearance, which will affect the intensity. Because of the roller fairlead in use, it is necessary to withstand the huge external force of the ship and it is necessary to ensure that the structure of the roller fairlead is stable, not damaged by the external force, with high requirements in strength.

A good roller fairlead manufacturer should use high-intensity materials and does a good job in processing and surface treatment, ensuring that there is no strength defect in the surface. Otherwise, even if there is no problem with the material intensity, it will also cause problems in the strength due to the surface defect, which will affect the normal functionality use.

The best manufacturer should adopt excellent quality material with the advanced process, then the color of the appearance will be uniform and bright.

2.Specifications

To select a quality roller fairlead, it is necessary to pay attention to the requirements on the specifications, the requirements on the specifications, which is required to transmit the cable on the specifications, because the cable has differences in size, length. The device that can be stored and used is also different from the specifications.

The best roller fairlead supplier should have different specifications to meet the requirements of the installation.

3. Environmental Restriction

Because of the different environments, there is a certain limit on the material of roller fairlead, especially for the marine equipment and the wear of metal device is very large. The requirements of corrosion resistance for the roller fairlead should be considered.

The supplier should adopt excellent corrosion resistance materials for superb roller fairlead.

4.Price

The price always is an important factor for choosing the best-value manufacturer. The most competitive prices with quality products can be a great advantage.

5.Craftsmanship

An excellent manufacturer & supplier should have advanced craftsmanship and strict quality requirements, which should meet the needs of effect and performance.

Summary

Roller fairlead plays an important role in mooring devices. The article introduces some professional knowledge about the roller fairlead including constitute, working principle, installation, maintenance and useful tips to help you find the best manufacturer & supplier.